What it's like partnering with Sterling Surfaces

photo: Tsoi/Kobus & Associates

Sterling Surfaces recently had the pleasure of working on a project to create a Solid Surface reception desk for the architecture firm Tsoi/Kobus & Associates new Boston office.

The following is an interview with industrial designer John Feidelson where he describes the project and what it was like working with Sterling Surfaces.

John, how did you discover Sterling Surfaces?

In 2004 I was developing a design for the curved plinth for a glass stair at a Boston law firm. I called around to various manufacturers of Solid Surface - Corian, Avonite, Staron. Sterling Surfaces’ name kept coming up as the people who love a challenge and take-on atypical work. When the job was bid Sterling Surfaces was awarded to job and ended up doing a large portion of the work on site. I was so impressed with the quality and skill of the workers. In the end it was a real collaboration between Architect, Sterling Surfaces, the metal fabricator and GC.

Collaboration is a bit of a cliché these days. What exactly do you mean?

Yeah, I know collaboration is overused but I really can’t think of any other way to describe my working process with Sterling Surfaces. As an industrial designer I have a good understanding of materials and manufacturing, but there is no better way to avoid pitfalls than working hand–in-hand with a fabricator like Sterling Surfaces that is at the forefront of R&D and fabrication in the Solid Surface world.

So how did this project come about?

A couple of years back I converted my one-car garage into a workshop where I tinker and occasionally take-on freelance projects designing and fabricating furniture. Tsoi/Kobus & Associates, the architecture firm I was working for, was moving into new downtown Boston offices. Everyone in the firm contributed something to the design effort. I designed the reception desk and when we priced it I discovered I could build it cheaper than the GC, so I camped out in my shop for a few months. It was a win-win for the firm since it showcases how hands-on we are as designers and I was able to ensure that my design was executed perfectly for the “client”.

Tell us about your process?

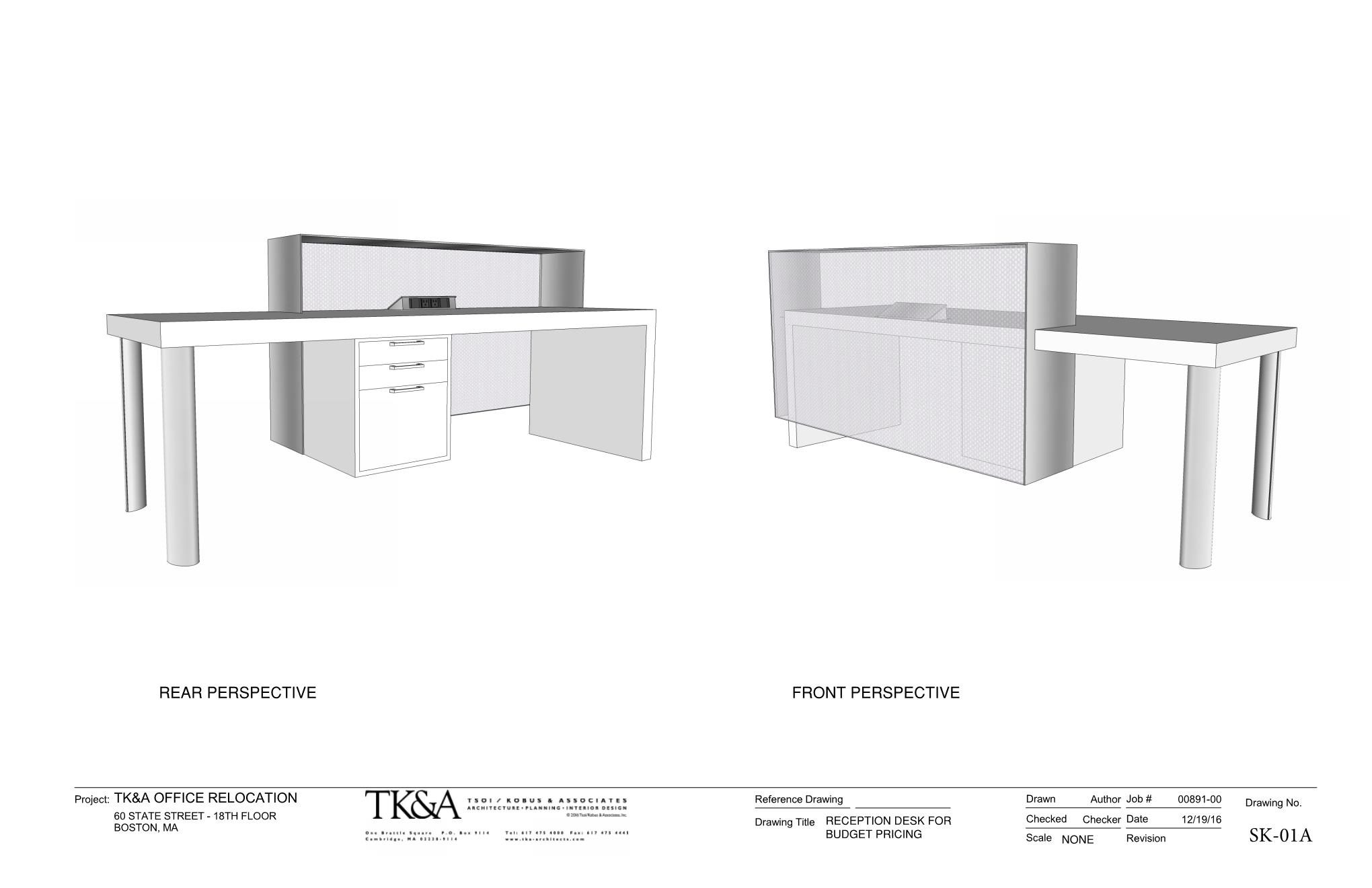

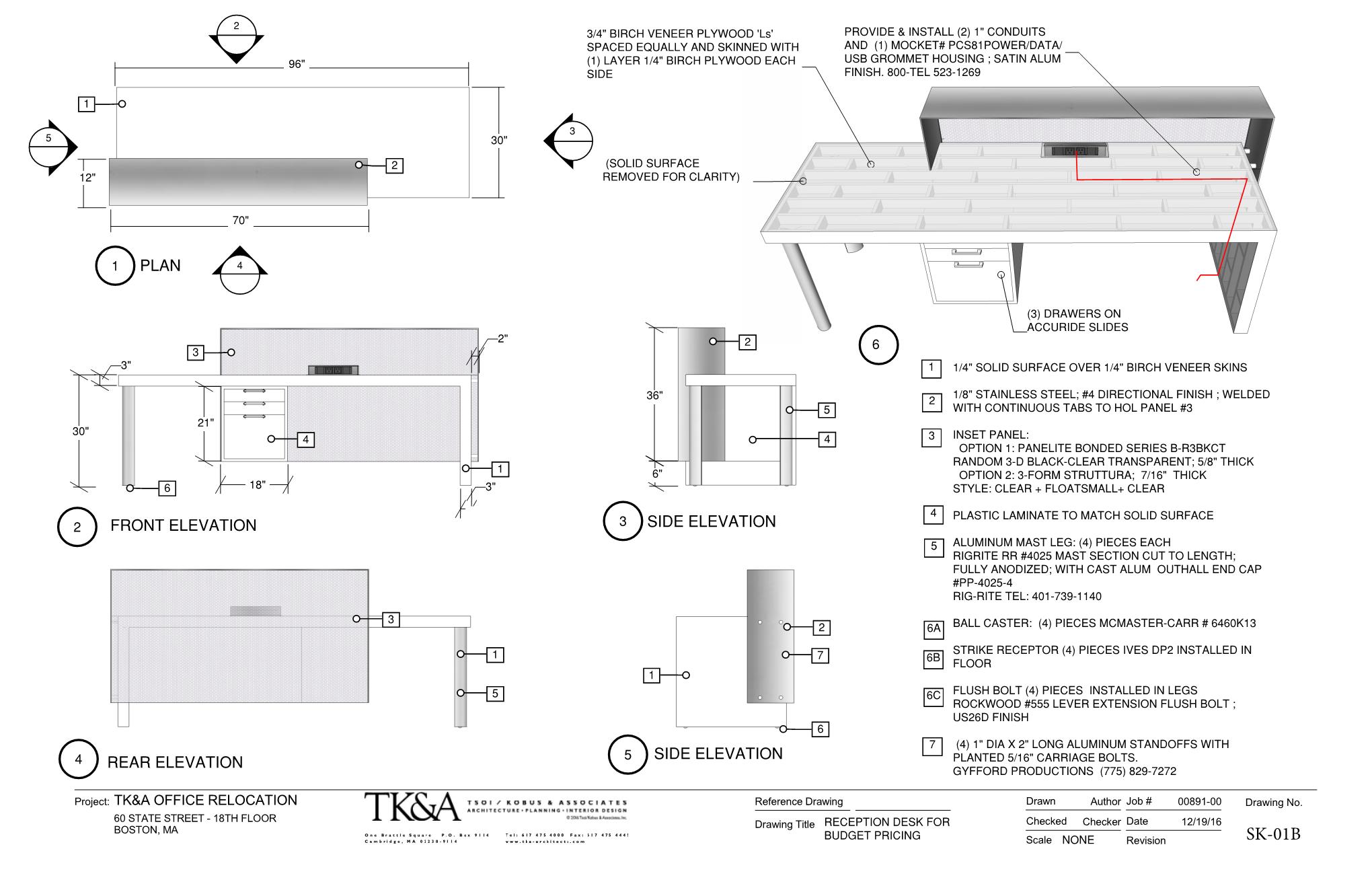

Well I first developed Sketch-Up drawings for client approval, and then I turned those into annotated drawings for a budget price. I sent these off to Rick Lasell at Sterling Surfaces and Joshua Kampa at Praxis in Providence a gifted designer/metal worker who does phenomenal work. I take care of all the woodwork, assembly and modifications necessary to bring the pieces and parts together. Rick responded immediately with a price and some suggestions for refinements to adhere to “best practices”.

What kind of suggestions?

He pointed out that, while architects usually detail Solid Surface counters as a build-up of substrate and Solid Surface, this causes issues with expansion and contraction. When fabricating counters, Solid Surface should not be bonded directly to a substrate. Rather, spaced strips are the way to go. This led to a redesign of the supporting structure inside because eliminating the skin compromised the box beam structure. Rick loves to get into the weeds so I was able to feel very confident his approach was the right one. He also commented on the detail I used for the file fronts (too thin) and advised using threaded inserts bonded into the fronts (no screws!)

Back to collaboration, any other thoughts?

Asking questions, understanding the process, and learning the language of a fabricator makes the whole process more of an adventure than just doing what you know. When I dropped off the framework for the Solid Surface at the Sterling Surfaces factory, Rick toured me around the facility and showed me how he has developed sophisticated one-of-a-kind tooling to solve fabrication challenges. The cool thing is that he is collaborating at the front end with architects and the back end with manufacturers. This kind of collaboration builds on the skills and knowledge of all parties involved. It’s not only creates strong relationships for future work but it makes the working together such an enjoyable experience.

On behalf of the Sterling Surface team I would like to thank you John and all of your associates for the input on this project, it’s been enjoyable for us as well. Thank you also for taking the time to give us your feedback. We look forward to collaborating with you on future projects!

photo: John Feidelson

photo: John Feidelson

photo: Tsoi/Kobus & Associates

photo: Tsoi/Kobus & Associates

photo: Tsoi/Kobus & Associates

photo: John Feidelson

photo: John Feidelson

photo: John Feidelson

photo: John Feidelson